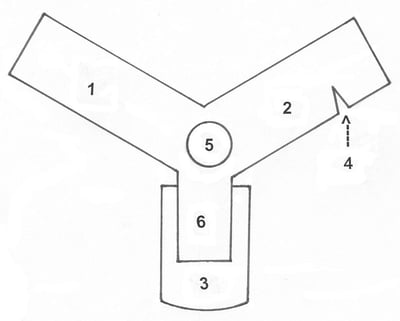

The idea from Wolfgang from Seevetal:

The triplet hammer consists of a metal track, a metal fin with a groove and a rubber hammer at an angle of 120 degrees.

Designation in the drawing

View from above:

1 – track

2 – fin

3 – rubber mallet

4 – groove

5 – Hole for the handle

6 – Fixing bolt for the rubber mallet

The customer's rating:

The hammer has turned out well. Only the screw to fix the handle is too big and could have been smaller and more elegant. But since it's just a pattern, it doesn't matter.

The story of the custom made triplet hammer (a new invention of mine).:

Negotiation phase

Good morning Benter,

if iron is not possible, brass is fine too. Aluminum would be too soft in my opinion.

Many greetings

Wolfgang

Hello Benter,

I just need a hammer now.

Many greetings and thank you,

Wolfgang

Kindly send the sizes so that we can begin to work

Good morning Benter,

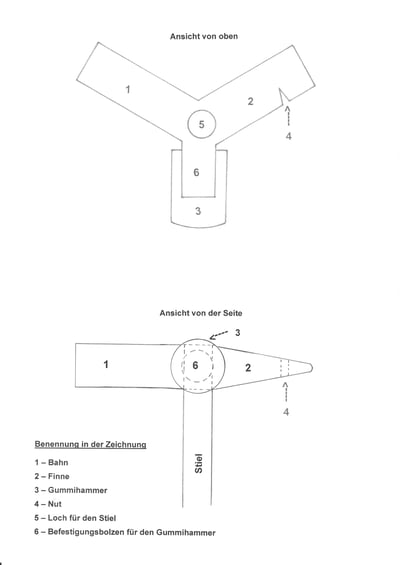

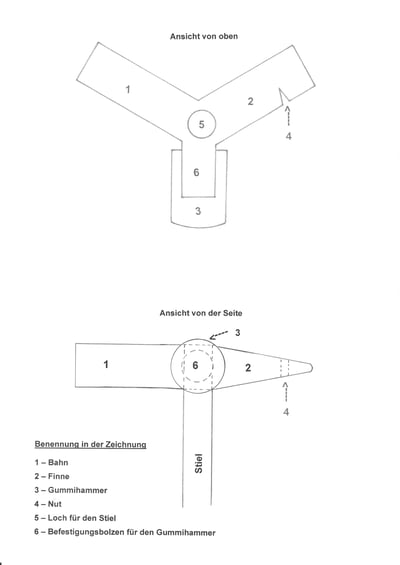

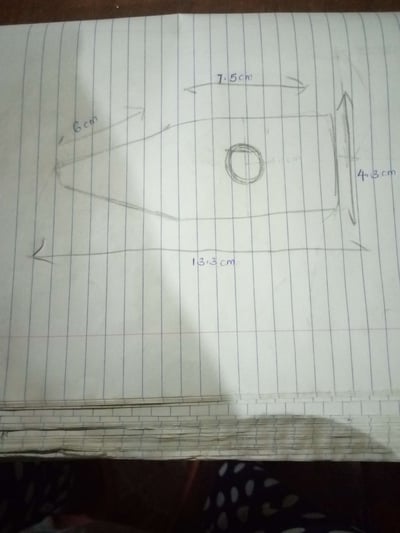

the lengths of 1 (track) and 2 (fin) are each about 6 cm to the center of 5 (the hole for the stem). The fastening bolt 6 can be about 4 cm long to the center of 5, and on top of it comes a rubber hammer, so the total length of the rubber hammer (6 3 together) is also about 6 cm.

Thank you very much and best regards,

Wolfgang

Hello Benter,

unfortunately you misunderstood my drawing. See the view from above and the view from the side on my drawing triplet hammer -1.

The angle between all 3 hammers is 120 degrees each.

Naming in the drawing:

1 - track, 6 cm long to the hole for the handle, 2 cm wide and 2 cm high.

2 - Fin, 6 cm long up to the hole for the handle, at the beginning 2 cm wide and 2 cm high, at the end 2 cm wide and 5 mm high

3 - Rubber cap on fixing bolt, 6 cm long and 3 cm in diameter

4 - groove, 5 mm wide and 1 cm deep

5 - Hole for the handle, 2 cm round or oval

6 - fixing bolt for the rubber hammer, 1 cm in diameter round and 4 cm long

I hope that I have explained it understandably. Otherwise please contact me again.

Many greetings

Wolfgang

I now understand your drawing better. And what about the thickness of the hammer??kindly

Hello Benter,

the width, thickness and length I have already given yesterday (see above) in centimeters and millimeters. Everything is approximate and does not have to be followed exactly, as it is only a sample for now.

Many greetings

Wolfgang

Production phase

Thank you Benter and have a nice weekend.

Thank you Benter and looking forward to your next info. Many greetings, Wolfgang.

Dear Benter,

two of the three sides look good. See in my drawing the numbers 1, 3 6 and 2. number 1 and 3 6 are correct! But number 2 should not be round, it should be as wide as number 1, but then become narrower towards the tip. If you can, please cut out a groove for pulling nails (see number 4), but it doesn't have to be. Thank you very much and best regards, Wolfgang.

Thank you.

Thank you!

Hi Benter,

My comment to your last photo 20210419_134500-753:

The rubber hammer (pointing down on the photo) is correct.

The round hammer (pointing to the right in the photo) should be SQUARE AND NOT ROUND!

Unfortunately, the left hammer with the white rubber is completely wrong (see my drawing triplet hammer-1 number 2)! It should also be squared and become narrower towards the tip!

If you can still mill out a groove there for pulling out nails, it would be nice. If not, it's fine too.

Please take a close look at my drawing triplet hammer-1.

Many greetings and thanks,

Wolfgang

I hope to have explained it understandably.

Hi Benter,

On your photo 20210419_154759_693 only the rubber hammer pointing upwards is correct, the other one is both wrong!

The hammer on the left should not be round but square 2 x 2 cm.

The hammer on the right is also square 2 x 2 cm and becomes narrower at the end. There also 2 cm wide but only 0.5 cm thick.

Please have a look at my drawing, it explains everything.

Many greetings,

Wolfgang

Thank you and have a nice end of the day.

Thank you!

Okay, I'm looking forward to your next feedback.

Have a nice evening after work and see you next time.

I have to enter okay or something again now, otherwise I can't get out of our correspondence.

Hello Benter, unfortunately I have to write something as feedback with every email from you, even if it is only an OK. Otherwise I can not delete the email.

I wish you a nice weekend and look forward to your next

feedback.

Is that the design now so that we can begin with the casting

Hi Benter,

it does not correspond exactly to my ideas and my drawing, but it is almost ok like that.

But the rubber mallet should be ROUND AND NOT SQUARE.

Many greetings

Wolfgang

We will make the rubber side round.so is it okay with you we cast it with this idea or we should change it again l understand one side is supposed to be a nail hammer design

Hi Benter,

if the rubber mallet is round, everything is good. It's just supposed to be a sample to show off.

Many greetings

Wolfgang

Okay

Thank you too and I look forward to finishing the hammer.

Hello Benter,

the hammer looks good like this. One side is square, the other side is pointed at the front and the third side is a round rubber mallet. Now only the handle of wood or metal is missing, then the hammer is ready.

Thank you Benter and I wish you another pleasant stress-free day.

Hello Benter, I wish you a relaxing weekend and look forward to the completion of the hammer.

Thank you dear Benter, I am looking forward to it.

Dear Benter, thank you for the videos and have a nice weekend.

Good day dear Benter, how is the hammer? Are you already finished? Many greetings and see you soon, Wolfgang.

Thanks Benter, have a nice weekend.

Good day Benter, I have the following comments:

1. can you also braze or weld the handle, because fixing it with a screw does not look so professional and good?

2. the handle and the hammer surfaces would all still have to be polished clean and smooth, because it looks so unprofessional and not nice.

3. the tip is not straight but slanted as I see in the photo. It would still need to be sanded straight.

I have attached two photos for you and marked them with arrow so you can see what I mean.

Many greetings,

Wolfgang

Thank you Benter and have a nice weekend.

Hello Benter, are you already done with the hammer? Many greetings and have a nice weekend. Wolfgang

Thank you for your information. I wish you a relaxing weekend.

Hello Benter, are you already done with the hammer? Many greetings, Wolfgang.

Dear Benter,

thank you for all your work and I look forward to receiving it soon. The hammer looks very good.

Many greetings,

Wolfgang

Dear Benter, stay healthy and maybe see you again sometime. Sincerely, Wolfgang.

Everything okay, I look forward to the delivery.

My name is Noel, local operations manager, Kenya. I'm currently doing the quality review and thought of sharing some close ups of the hammer. I've noted it has some minor dents. Should I still ship it as it is. Kindly let me know and I'll ship the hammer as early as Monday.

Regards

Noel

Dear Noel, the quality is really bad. There are several holes or flaws in the metal to be seen. In addition, a countersunk screw to fix the handle would be much more elegant than a large hexagonal screw, which seems to have been used before and looks worn. The handle is very poorly painted and some of the bare metal is still visible. I can't imagine the hammer looking like this to a DIYer. Thank you very much for your advice, which I did not recognize from the photos. Best regards and have a nice weekend. Wolfgang

Hello Benter, on your photos I have unfortunately not seen the errors. In this respect it was good that Noel paid attention and the hammer will now hopefully be very good, so that I can then present it to the magazines at some point. Many greetings, Wolfgang.

Good morning Benter, thank you for the information.

Good day Benter, how are you getting on with the hammer? Many greetings, Wolfgang.

Hello Benter, for 12 days I have heard nothing from you. What is the hammer doing? Many greetings, Wolfgang.

Thank you also Benter.

Hello Benter, are you making good progress with the hammer? Many greetings, Wolfgang

Good morning Benter. How are you getting on with the hammer? Best regards, Wolfgang.

Hello Benter, are you ready? Many greetings, Wolfgang.

Good morning Benter, are you ready? Because you wanted to send it on Tuesday the 13th of July. Many greetings, Wolfgang.

Good morning Benter, I hope and look forward to the delivery soon. With best regards, Wolfgang.

Until today I have unfortunately not yet received a delivery.

Thank you, looking forward to the delivery.

(Automatic translation) 28 Jul 2021 15:04 pm: Wolfgang.

(Automatic translation) 28 Jul 2021 15:04 pm: Wolfgang.

Thank you, looking forward to the delivery.

The final custom made triplet hammer (a new invention of mine).:

Reference: ON004960E-23769

Costs to realize this custom made triplet hammer (a new invention of mine).

| Price | |

|---|---|

| Cost of material |

39.58

|

| Cost of labour |

41.56

|

| Cost of packaging |

0

|

| Cost of delivery to local operations manager |

3.96

|

| Subtotal – payout to craftsman |

85.1

|

| Customer aquisition costs (advertising etc.) |

8.51

|

| Handling fee Urban Change Lab |

8.51

|

| Shipping costs from Kenya to Germany* |

20

|

| VAT (Germany)* |

19.4

|

| Total |

145.32

|

Leave a Reply